In the radiation protection (RP) field, we focus intensely on the idea of keeping all radiological risks and doses as low as reasonably achievable (ALARA). This preventative principle should underscore the basis of every RP decision you make.

A well-designed RP program is likely to be successful in consistently keeping doses low, however without taking measurements, there is no way to be certain or demonstrate that doses are indeed remaining low. One of the best ways to validate and demonstrate that your program is working as intended is to back it up with a robust personnel dosimetry program.

What is personnel dosimetry?

Personnel dosimetry for external exposures[1] (is the use of wearable radiation dose measurement instruments called dosimeters to determine the radiation dose received by individuals in the workplace.

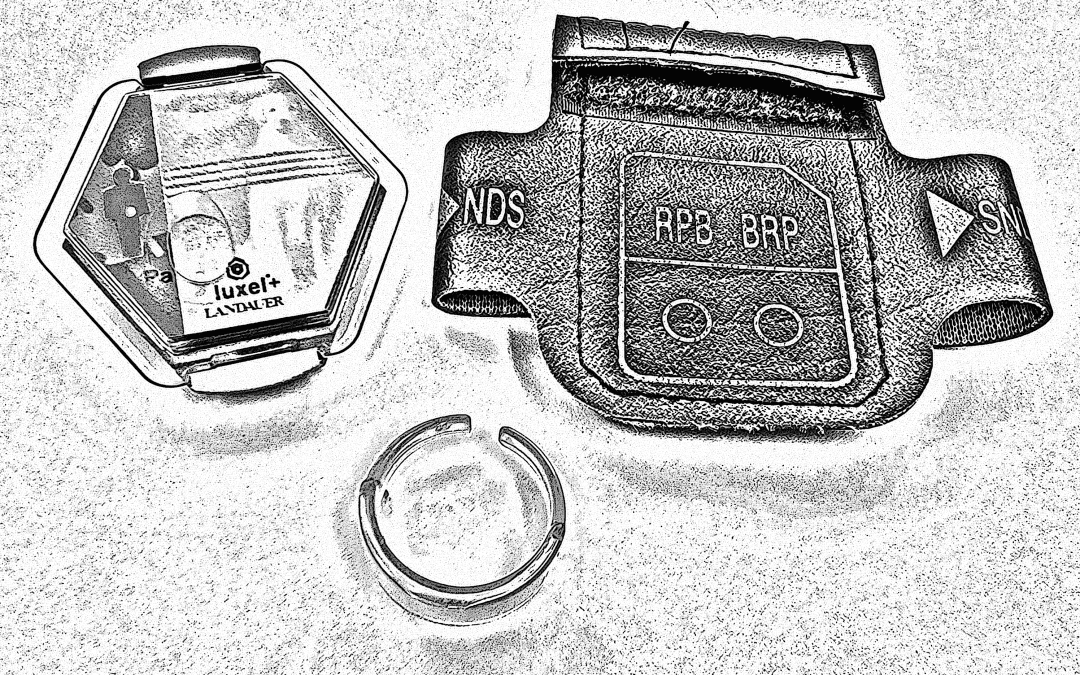

Dosimeters are available in various forms, which can be broadly categorized into those which can be actively read, such as direct read dosimeters (DRDs) or electronic personal dosimeters (EPDs), and those that are passive devices which must be read by a dedicated reader, such as thermoluminescent dosimeters (TLDs) or optically stimulated luminescence dosimeters (OSLDs).

DRDs and EPDs have certain advantages in specific situations but generally speaking, passive dosimeters like TLDs and OSLDs are more practical for long-term personnel dosimetry programs. Therefore, this article will focus on those devices and their application.

TLDs and OSLDs operate on different, but similar, technology and are normally used to monitor exposure to radiation in the form of photons (gamma radiation or x-rays) and beta particles. In both types of dosimeters, radiation interacts with a material in the device which causes electrons to be trapped in an excited state. A large number of these excitations can accumulate in the material, which means that TLDs and OSLDs can be used for a long time and can also measure a wide range of doses. The material is later removed from the device and put into a reader which releases and counts the trapped electrons to determine the dose received.

Typically, each dosimeter device will have multiple chips of this TL/OSL material, which are placed under different filters to help determine dose received to different depths of tissue, allowing one to relate the measured quantities to various regulatory limits. Depending on the application, usually two or three chips are used to determine different operational quantities, which are indicated by Hp(mm depth):

- Hp(10): The dose received at 10 mm tissue depth, used to represent whole body dose or “deep dose”

- Hp(3): The dose received at 3 mm tissue depth, used to represent dose to the lens of the eye

- Hp(0.07): The dose received at 0.07 mm tissue depth, used to represent dose to skin

Depending on the need at the workplace and the supplier capabilities, one may be able to add additional materials to the dosimeter, to determine dose from other radiation types (e.g., neutron dosimetry).

When is personnel dosimetry required?

For all work performed under a CNSC license, personnel dosimetry is required whenever a Nuclear Energy Worker has a reasonable probability of receiving either:

- An effective dose greater than 5 mSv in one calendar year, and/or

- An equivalent dose to the skin, or the hands and feet greater than 50 mSv in one calendar year

Also, because it can be difficult to quantify what a ‘reasonable probability’ is, it is instead generally recommended to implement a dosimetry program if it’s possible based on daily operations for workers to reach levels about 5 times lower than those. It is also recommended in case an incident or accident could result in doses of this magnitude.

Note that there is a requirement in the CNSC’s Radiation Protection Regulations (Section 19) for dosimetry data collected on workers to be submitted to Health Canada’s National Dose Registry. This requires further informational on the worker including, among other things, their social insurance number. Ensure that you collect all the necessary information when providing your workers with dosimeters.

There are also requirements for dosimetry for work performed under provincial legislation such as x-ray facilities. Using Ontario as an example, the requirement in OHSA Regulation 861: X-Ray Safety is that any worker who meet the definition of an ‘X-Ray Worker’ requires dosimetry, regardless of the specifics about the type or magnitude of expected dose. This does vary by province, so please consult your provincial regulations.

What is required for providing personnel dosimetry?

The Canadian Nuclear Safety Commission (CNSC) has a licence category for dosimetry service providers. If you are measuring personnel radiation dose to meet the requirements of a CNSC license or regulation, or a provincially regulated radiological activity (e.g. the use of x-ray equipment under 1 MeV), you must use a CNSC-licensed dosimetry provider.

These providers maintain their CNSC license by meeting all the requirements described in CNSC REGDOC 2.7.2, Dosimetry, Volume II: Technical and Management System Requirements for Dosimetry Services.

Individual companies may obtain a CNSC licence to provide dosimetry to their facility staff[2], or companies may use a commercial dosimetry service provider. There are three CNSC-licenced dosimetry service providers who can provide commercial external dosimetry in Canada:

Personal dosimeters are used for a determined period after which they are returned to the provider to be analyzed, and the workers are provided with replacement dosimeters for the next dosimetry period. A typical dosimetry period has the dosimeters exchanged on a quarterly frequency, but other periods/frequencies are available to suit the user’s needs (e.g., monthly or bi-weekly).

How do workers wear them?

How a worker will wear their dosimeter(s) will depend on the type of exposures possible at the workplace. If a worker’s exposure to radiation will be the same level from head to foot, one dosimeter badge worn on the front of the torso, typically between the waist and shoulders, is sufficient. If different parts of the body may be exposed to different levels of radiation, multiple dosimeters may be required. Some examples of situations requiring multiple dosimeters are below:

- Someone who is directly handling radioactive material or has their hands placed close to a radioactive source may be required to wear an extremity dosimeter on their hands (usually in the form of a ring dosimeter or a wrist strap) in addition to the whole body dosimeter on the torso.

- A worker who is wearing lead protection (e.g., a lead apron) may need to wear one whole body dosimeter under the lead protection (to measure the dose to the body where it is protected by the lead) and another dosimeter outside the lead protection such as at neck level (to measure the dose to the parts of the body that are not protected by the lead, such as the face and eyes[3]).

If a worker needs to wear personal protective equipment and clothing (PPE&C) to protect them from contamination (e.g., wearing a protective suit or gloves), the dosimeter should be worn under the PPE&C so that it is also protected from the contamination.

How to review dose data

Once you establish your dosimetry program, you are going to have a lot of data on your hands. To use it effectively, a few key strategies are recommended.

Start by determining all applicable limits. This should include at least two of the below levels for each dosimeter type, with the third also strongly recommended:

- The applicable regulatory dose limit(s).

- More than one dose limit may apply, depending on the type of radiation exposure possible in the workplace. For example, if a worker is exposed uniformly from head to foot, then the regulatory limits that are likely to apply would be the effective dose (whole body) and the equivalent skin dose limit. If there is direct handling of radioactive material or potentially higher exposures to the hands or feet, then the equivalent extremity dose limit may also apply. If dose to the face may be different than to the whole body, then the equivalent dose to the lens of the eye may apply.

- An ‘Action Level’.

- Action levels are required for facilities working under a CNSC license and are recommended as a good practice for workplaces regulated by the province/territory. In the CNSC Radiation Protection Regulations, an Action Level is defined as “a specific dose of radiation or other parameter that, if reached, may indicate a loss of control of part of a licensee’s radiation protection program and triggers a requirement for specific action to be taken.” Action levels are designed to alert licensees before regulatory dose limits are reached and for CNSC licensees, are specified in the radiation protection program and/or the licence. An action level created for personnel dose would normally be set at a dose value below the worker’s regulatory limit but above what would typically be received by a worker. If an action level is reached, there must be an investigation into the cause of the unusual dose and actions taken to prevent a reoccurrence. For CNSC licensees, the results of the investigation must be reported to the CNSC.

- An ‘Internal Investigation Level’ (IIL)

- This level is set lower than an Action Level, and is an internal process control measure where you would investigate doses to catch errors and continuously improve, but do not need to report them.

Action Levels and Internal Investigation Levels, these levels should be implemented for the regular dosimetry period and annually (unless your dosimetry period is only annual, in which case one would only have annual values). To assist with this, each dose report you receive from a dosimetry supplier will typically have the doses reported for the specified period, as well as a ‘Year to Date’ dose.

To provide an example, consider a workplace where whole body and extremity (hand) doses are possible. If the workplace assessment is that workers are likely to get no more than 4 mSv in a year for whole body effective dose, and no more than 80 mSv in a year to the hands, the control levels put in place may look something like the following:

Whole Body Effective Dose (compared to Hp(10) from Body Dosimeter)

| Period | Regulatory Limit | Action Level | Internal IL |

| Quarterly | N/A | 2.5 mSv | 1 mSv |

| Annual (YTD) | 20 mSv[4] | 5 mSv | 2 mSv |

Hand Extremity Dose (compared to Hp(0.07) from Ring Dosimeter)

| Period | Regulatory Limit | Action Level | Internal IL |

| Quarterly | N/A | 50 mSv | 20 mSv |

| Annual (YTD) | 500 mSv | 100 mSv | 50 mSv |

For each dose report you then receive, you would review the reported worker doses for any instances of these levels being exceeded, or trending to be exceeded, and take the appropriate action(s).

Depending on the complexity of the workplace, you may have diverse staff groups to monitor, for whom you may want to establish different Action Levels and IILs, so this can quickly become fairly complex. Digital solutions may be practical, however should only be used as a supplement to direct review.

Also, be sure to keep records of all dose reports and any actions you’ve taken in response to levels being exceeded. The CNSC requires dosimetry records to be kept for at least five years (provincial requirements may vary), however it is recommended to keep them for the maximum reasonable time.

Finally, you should also establish a method to communicate each workers’ dose results to them on at least an annual basis. This is required for CNSC licensees and is a good practice in other workplaces. Ensure you do this with respect to your organizations privacy and data security policies, as this information may be subject to personal health information privacy requirements.

That’s a Wrap

Thanks for reading today’s post on establishing an effective personnel dosimetry program. This should provide you with a solid foundation to build your program upon.

More detailed guidance on the application of a personnel dosimetry program can be found in CNSC REGDOC 2.7.1, Dosimetry, Volume I: Ascertaining Occupational Dose.

[1] An external exposure occurs when the source of the radiation is external to the person, or outside the person’s body, such as an x-ray machine or radiation source located beside a person. Conversely, an internal exposure occurs when radioactive material makes its way into a person’s body, and the radiation is emitted when the material is within the body. Determination of dose for intakes of radioactive material (or internal dosimetry) is beyond the scope of this article.

[2] Obtaining a CNSC licence to perform dosimetry can be both costly and complex, and therefore tends to only be performed by very large organizations with significant in-house RP expertise.

[3] Eye dose measurement is garnering more attention recently due to a gradual updating of international dose limits. There are other circumstances where eye dose measurement is indicated than only when lead is protecting the body dosimeter. For more details, see REGDOC 2.7.2, Volume I.

[4] Assuming you take the CNSC 5-year limit and convert it to an annual limit, which is recommended in most cases.