We, as humans, have no sense by which to detect ionizing radiation, a known carcinogen. In order to be able to measure the level of ionizing radiation in an area, instruments must be used. Even levels of ionizing radiation capable of causing immediate health effects are imperceivable to our senses.

Definition and Importance

Canada’s Nuclear Regulator, the Canadian Nuclear Safety Commission (CNSC[i]), defines calibration as “[t]he process to verify that, with a known precision input, a model, instrument or channel parameter gives the required output.”[ii] So for radiation measurement equipment, it is the process of using known sources of radiation with known strengths to verify that a measurement instrument is reading correctly.

Because of our reliance on measurement instruments for the safety of people and the environment, it is vital that these instruments are reading accurately. Otherwise, using the instrument is a at best meaningless. At worst, it could lead to serious consequences due to making decisions based on incorrect information.

The concept of calibration is so important that ISO 9001:2015 has a subsection, 7.1.5.2(a), specifically addressing it: “When measurement traceability is a requirement or is considered by the organization to be an essential part of providing confidence in the validity of measurement results, measuring equipment shall be: calibrated, or verified, or both, at specified intervals, or prior to use, against measurement standards traceable to international or national measurement standards; when no such standards exist, the basis used for calibration or verification shall be retained as documented information;”[iii]

Types of Measurement Equipment

If asked to name a piece of radiation measurement equipment, many people in the general public would know about Geiger(-Mueller) counters or the badges worn by their x-ray technicians. In the radiation protection industry, however, the variety of types of measurement equipment available are as varied as the applications of radiation science and engineering they support. Common broad categories include:

- Survey meters;

- Contamination monitors, including hand and foot monitors;

- Dosimeters, for both external and internal sources);

- Bioassay, including whole body counters and liquid scintillation counters;

- Grab samplers;

- Continuous monitors;

- Leak test counters; and

- Swipe counters

to name a few. Each category utilizes the properties of the radiation they are measuring (α, β, γ, n, x-ray, neutrinos, or other exotic types from cosmic radiation or particle accelerators) in order to have the radiation interact with material and be detected. Common constructions include

- Cylindrical gas chambers which use an electric field to detect ionization (ion chamber, proportional counter, Geiger-Mueller counter);

- Those built to interpret the light signal given off from a material which gives off visible light when radiation interacts with it, called a scintillant;

- Crystals build to store a record of the fact that they encountered radiation until heated or hit with a laser; and

- Diode detectors which use electronics to track and report the amount of radiation present.

Although not as commonly used, tracks made on film are still the basis for measurement in some applications. Bubbles formed in liquid polymers are another example of a less common measurement method.

There are many formats and geometries for radiation detection instruments. Often it is impossible to tell the inner workings of an instrument just from looking at it. Instruments with very different measurement ranges, features, and capabilities can look very similar. It is important to match the expected source and strength of the radiation being detected to the features of the instrument being used. A perfectly calibrated instrument cannot detect radiation of types it is not designed to detect or levels of radiation outside its measurement range, both in terms of the strength of the field and energy of the radiation.

CNSC

The CNSC refers to calibration in many of its Regulatory Documents[iv]. Major sections of REGDOCs dedicated to the topic include:

- REGDOC-1.6.1, Licence Application guide: Nuclear Substances and Radiation Devices Appendix Z: Regulatory Expectations for Calibration of Survey Meters[v];

- REGDOC-2.7.1, Radiation Protection, Section 25.3: Calibration of Instruments and Equipment Used for Radiation Measurements[vi];

- REGDOC-2.7.1, Radiation Protection, Appendix D: Calibration of Radiation Survey Meters and Direct Reading Dosimeters[vii];

- REGDOC-2.7.2, Dosimetry, Volume I: Ascertaining Occupational Dose, Section 10: Calibration[viii];

- REGDOC-2.7.2, Dosimetry, Volume I: Ascertaining Occupational Dose, Appendix E, Section 8: Instrument Calibration[ix]; and

- REGDOC-2.7.2, Dosimetry, Volume II: Technical Management System Requirements for Dosimetry Services, Section 7.10: Calibration and Maintenance[x].

In its 2021 Regulatory Oversight Report on the Use of Nuclear Substances in Canada, the CNSC noted calibration of survey meters as being a major source of non-compliance:

The most frequent non-compliances have consistently been related to the lack of management oversight in the implementation of the radiation protection program. Items of non-compliances frequently include the failure of workers to conduct thyroid monitoring in accordance with their licence conditions, the failure to demonstrate that sampling and counting methods meet licence criteria for detecting loose contamination and the failure to calibrate survey meters at the required frequency.[xi]

X-Rays

Not all ionizing radiation in Canada is regulated by the CNSC. Naturally Occurring Radioactive Materials not involved in the nuclear power stream and x-rays under 1 MeV are regulated by the province, territory, or the federal government for federally-regulated workplaces. Some jurisdictions will refer to calibration requirements set by the CNSC, others will have their own specifications, while others have no set standards in their regulations, but it would be expected to use best practices in radiation protection to meet the expectations of general duty clauses under OHS and environmental protection legislation.

Health Canada publishes a number of Safety Codes[xii], which are legally-binding in federally-regulated workplaces under the Canada Labour Code Occupational Health and Safety Regulations 10.26 (2)[xiii]. They are also adopted into regulation in some provincial/ territorial jurisdictions. They also have guidance documents which are not legally binding. With respect to calibration and x-rays, there are specific quality control tests required to be performed. It is important to remember that the instruments involved, such as light meters , irradiation time meters, and DAP meters must be calibrated.

As an example of guidance found within these documents, Safety Code 35: Safety Procedures for the Installation, Use and Control of X-ray Equipment in Large Medical Radiological Facilities requires the development of guidelines for the calibration and maintenance of radiation measuring equipment and other test equipment (Section 1.3.1 iv) and that all sensitometric and densitometric equipment, dose meters, tube voltage meters should be calibrated on a regular basis according to manufacturers’ recommendations (Section 4.1.2) as part of a quality assurance program.[xiv]

How to Have Instruments Calibrated

Most users of radiation measurement instruments rely on external professionals: either from the manufacturer or a calibration service business. For those with licences with the CNSC, their requirements for calibration outlined previously must be met. Documentation must show the CNSC’s procedures were followed, whether they are calibrating instruments themselves or using an external service.

For other jurisdictions, if a workplace wishes to do their own calibrations, in lieu of regulations which state how instruments should be calibrated, best practices in the industry should be followed. With that in mind, the CNSC materials could be used. Also available are also international standards such as the IAEA’s Calibration of Radiation Protection Monitoring Instruments[xv] or the following ANSI standards for Health Physics Instrumentation:

- ANSI N42.17A:2003 American National Standard Performance Specifications for Health Physics Instrumentation-Portable Instrumentation for Use in Normal Environmental Conditions

- ANSI N42.17b-1989 Performance Specifications for Health Physics Instrumentation – Occupational Airborne Radioactivity Monitoring Instrumentation, American National Standard

- ANSI N42.17c-1989 Performance Specifications for Health Physics Instrumentation Portable Instrumentation for Use in Extreme Environmental Conditions, American National Standard

- IEEE/ANSI N42.17AC-2022 American National Standard Performance Specifications for Health Physics Instrumentation-Portable Survey Instrumentation for Use in Normal and Extreme Environmental Conditions.[xvi]

Consumer Products

Outside of workplaces, people have interest in measuring ionizing radiation. There is background radiation around us all the time everywhere we go; we just cannot sense it. Radon gas is a major contributor to our background radiation dose and the second leading cause of lung caner. Hobbyist collectors sometimes wish to check artifacts for radiation. It is important that, whatever the reason for purchasing a consumer radiation detection instrument, that it should be able to be calibrated. And it should be calibrated at least every 12 months.

Final Thoughts

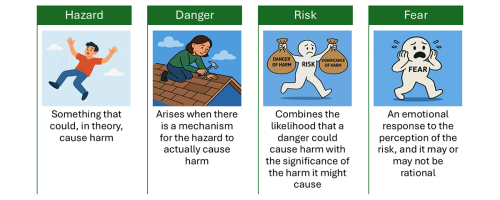

Because ionizing radiation can have serious health effects, we need to be able to detect when the levels are placing humans or the environment at unacceptable risk. We cannot detect ionizing radiation using our senses, so we must rely on measurement instruments. No matter the type of instrument being used, calibration is required to ensure that the information being reported is accurate. While some regulators provide detailed requirements, in other cases using best practices and standards from industry is expected. Calibration is a critical part of quality assurance and confidence in health and safety programming.

[i] Canadian Nuclear Safety Commission. Canadian Nuclear Safety Commission. (2014, February 3). https://nuclearsafety.gc.ca/

[ii] Canadian Nuclear Safety Commission. REGDOC-3.6, Glossary of CNSC Terminology. https://www.nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc3-6/

[iii] International Organization for Standardization. (2015). Quality management systems – Requirements (ISO/DIS Standard No. 9001:2015(en)). Retrieved from https://www.iso.org/obp/ui/en/#iso:std:62085:en

[iv] Canadian Nuclear Safety Commission. Regulatory documents. Canadian Nuclear Safety Commission. http://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/index.cfm

[v] Canadian Nuclear Safety Commission, REGDOC-1.6.1, Licence Application Guide: Nuclear Substances and Radiation Devices. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc1-6-1/index.cfm#app-z

[vi] Canadian Nuclear Safety Commission, REGDOC-2.7.1, Radiation Protection. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc2-7-1/index.cfm#sec25-3

[vii] Canadian Nuclear Safety Commission, REGDOC-2.7.1, Radiation Protection. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc2-7-1/index.cfm#secD

[viii] Canadian Nuclear Safety Commission, REGDOC-2.7.2, Dosimetry, Volume I: Ascertaining Occupational Dose. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc2-7-2-vol-I/index.cfm#sec10

[ix] Canadian Nuclear Safety Commission, REGDOC-2.7.2, Dosimetry, Volume I: Ascertaining Occupational Dose. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc2-7-2-vol-I/index.cfm#appx-E8

[x] Canadian Nuclear Safety Commission, REGDOC-2.7.2, Dosimetry, Volume II: Technical and Management System Requirements for Dosimetry Services. https://nuclearsafety.gc.ca/eng/acts-and-regulations/regulatory-documents/published/html/regdoc2-7-2-v2/index.cfm#sec7-10

[xi] Canadian Nuclear Safety Commission, Regulatory Oversite Report on the Use of Nuclear Substances in Canada: 2021. Regulatory Oversight Report on the Use of Nuclear Substances in Canada: 2021 – Canadian Nuclear Safety Commission

[xii] Canada, H. (2023, June 22). Government of Canada. Publications – Health risks and safety – Safety Codes. https://www.canada.ca/en/services/health/publications/health-risks-safety.html#a1.2

[xiii] Canada Occupational Health and Safety Regulations (SOR/86-304) 10.26 (2) https://laws-lois.justice.gc.ca/eng/regulations/sOr-86-304/page-17.html#h-894552

[xiv] Health Canada, Safety Code 35: Safety Procedures for the Installation, Use and Control of X-ray Equipment in Large Medical Radiological Facilities. https://www.canada.ca/en/health-canada/services/environmental-workplace-health/reports-publications/radiation/safety-code-35-safety-procedures-installation-use-control-equipment-large-medical-radiological-facilities-safety-code.html

[xv] International Atomic Energy Agency. (2000, March 3). Safety Report Series 16, Calibration of Radiation Protection Monitoring Instruments. https://www.iaea.org/publications/5149/calibration-of-radiation-protection-monitoring-instruments

[xvi] Health Physics Instrumentation. ANSI Webstore. https://webstore.ansi.org/search/find?in=1&st=health%2Bphysics%2Binstrumentation